Introducing the Analog 4120 code name: “i-captor”

An old friend just got better

In 1968 Weber introduced the very first thermal flow switch for liquids called the 4120. Because it was specifically built for the harsh environments of the steel industry where instruments are judged on their longevity, an additional innovation ensured the instrument would maintain its accuracy almost indefinitely.

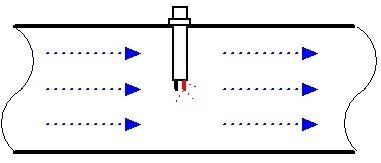

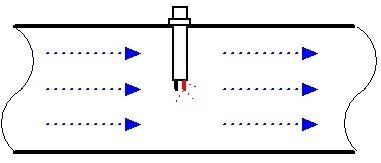

As illustrated below, a typical thermal flow sensor uses two perfectly matched elements to measure flow. One element is heated above the temperature of the medium while the other is not. By measuring the heat loss of the heated element compared to the non-heated element, flow can be measured very accurately.

Thermal flow meters are well respected for their reliability however; eventually the two sensors will drift apart resulting in a substantial loss of accuracy.

Weber overcame this problem by designing the 4120 to use a single element, a patent that still exists today. Even though the 4120 was and still is more accurate than the competitors who later tried to copy it, analog electronics limited its use to switching. By using modern day micro-processors and advanced mathematics we have substantially improved accuracy making the i-captor both an accurate and inexpensive alternative for reliable monitoring of flow.

The i-captor is simple, easy to install, very affordable and inherits Weber’s legendary reliability. It does not suffer from accuracy losses due to changes in fluid temperature, has a better than 2% accuracy over range with better than 2% repeatability.

It is the ideal choice for most water monitoring jobs from large chilled water systems with up to 20” pipes to just about any process need.

Loaded With Features and We Throw In Temperature Measurement For Free

The i-captor includes standard features such as highly accurate temperature sensing and is available in either analog or Modbus versions. The analog version provides two linier 4-20 mA outputs of both flow and temperature. The Modbus version also includes a flow totalizing counter. A single button sets the flow range on the analog version.

Features

Introducing the Analog 4120 code name: “i-captor”

An old friend just got better

In 1968 Weber introduced the very first thermal flow switch for liquids called the 4120. Because it was specifically built for the harsh environments of the steel industry where instruments are judged on their longevity, an additional innovation ensured the instrument would maintain its accuracy almost indefinitely.

As illustrated below, a typical thermal flow sensor uses two perfectly matched elements to measure flow. One element is heated above the temperature of the medium while the other is not. By measuring the heat loss of the heated element compared to the non-heated element, flow can be measured very accurately.

Thermal flow meters are well respected for their reliability however; eventually the two sensors will drift apart resulting in a substantial loss of accuracy.

Weber overcame this problem by designing the 4120 to use a single element, a patent that still exists today. Even though the 4120 was and still is more accurate than the competitors who later tried to copy it, analog electronics limited its use to switching. By using modern day micro-processors and advanced mathematics we have substantially improved accuracy making the i-captor both an accurate and inexpensive alternative for reliable monitoring of flow.

The i-captor is simple, easy to install, very affordable and inherits Weber’s legendary reliability. It does not suffer from accuracy losses due to changes in fluid temperature, has a better than 2% accuracy over range with better than 2% repeatability.

It is the ideal choice for most water monitoring jobs from large chilled water systems with up to 20” pipes to just about any process need.

Loaded With Features and We Throw In Temperature Measurement For Free

The i-captor includes standard features such as highly accurate temperature sensing and is available in either analog or Modbus versions. The analog version provides two linier 4-20 mA outputs of both flow and temperature. The Modbus version also includes a flow totalizing counter. A single button sets the flow range on the analog version.

Features